Future Innovations in Best Tray Sealing Machines Shaping 2025 Industry Trends

In 2025, the landscape of food packaging is poised for transformation, particularly with advancements in tray sealing machines. According to a recent study by MarketsandMarkets, the global tray sealing machine market is projected to reach USD 3.1 billion by 2025, growing at a CAGR of 5.6% from 2020. This growth is driven by the increasing demand for convenience foods, rising health consciousness among consumers, and the need for eco-friendly packaging solutions. Tray sealing machines are versatile, catering to a wide variety of products, including fresh produce, ready meals, and pharmaceutical items. Their ability to extend shelf life while maintaining product integrity positions them as a crucial technology in the packaging industry.

As we delve into the different types of tray sealing machines and their specific applications, it becomes clear how these innovations are shaping the future of food packaging and influencing industry trends.

Emerging Technologies Revolutionizing Tray Sealing Machines in 2025

The tray sealing machine industry is on the cusp of significant transformation as we approach 2025, driven by emerging technologies that promise to enhance efficiency and sustainability. According to a recent report from Markets and Markets, the global tray sealing market is expected to grow from USD 1.02 billion in 2020 to USD 1.53 billion by 2025, reflecting a compound annual growth rate (CAGR) of 8.5%. This surge can be attributed to advancements in automation and smart technology integration, which enable manufacturers to optimize production processes and reduce labor costs.

One of the most notable innovations is the incorporation of IoT (Internet of Things) capabilities within tray sealing machines. As highlighted in a study by Grand View Research, IoT enables real-time monitoring and predictive maintenance, significantly minimizing downtime. Additionally, the development of eco-friendly sealing materials is reshaping the industry's focus on sustainability. A report from Allied Market Research indicates that biodegradable and recyclable materials are poised to gain popularity, catering to the growing consumer demand for environmentally responsible packaging solutions. This shift not only benefits the planet but also aligns with industry regulations aimed at reducing plastic waste.

The Role of Automation in Enhancing Efficiency of Sealing Processes

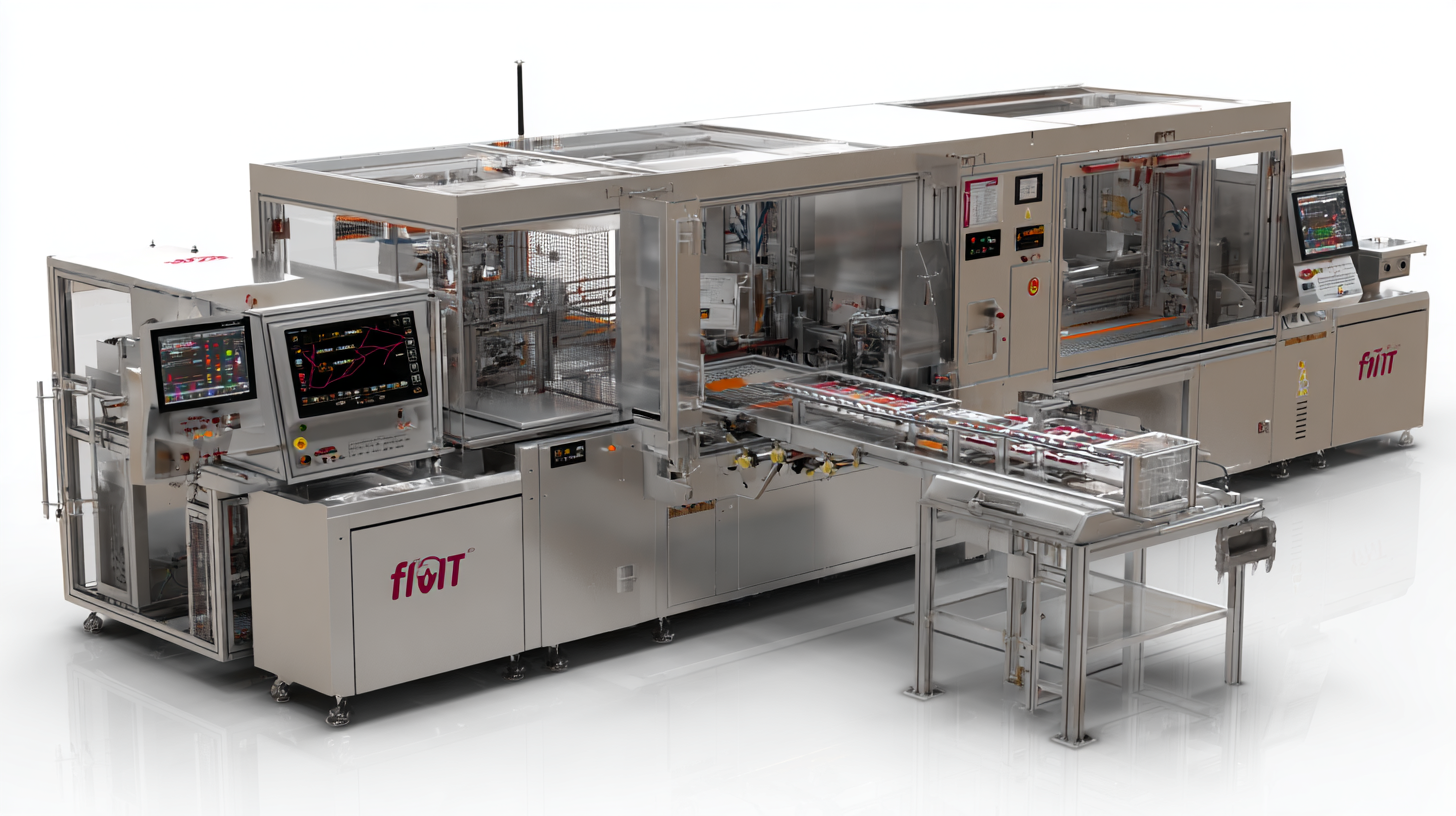

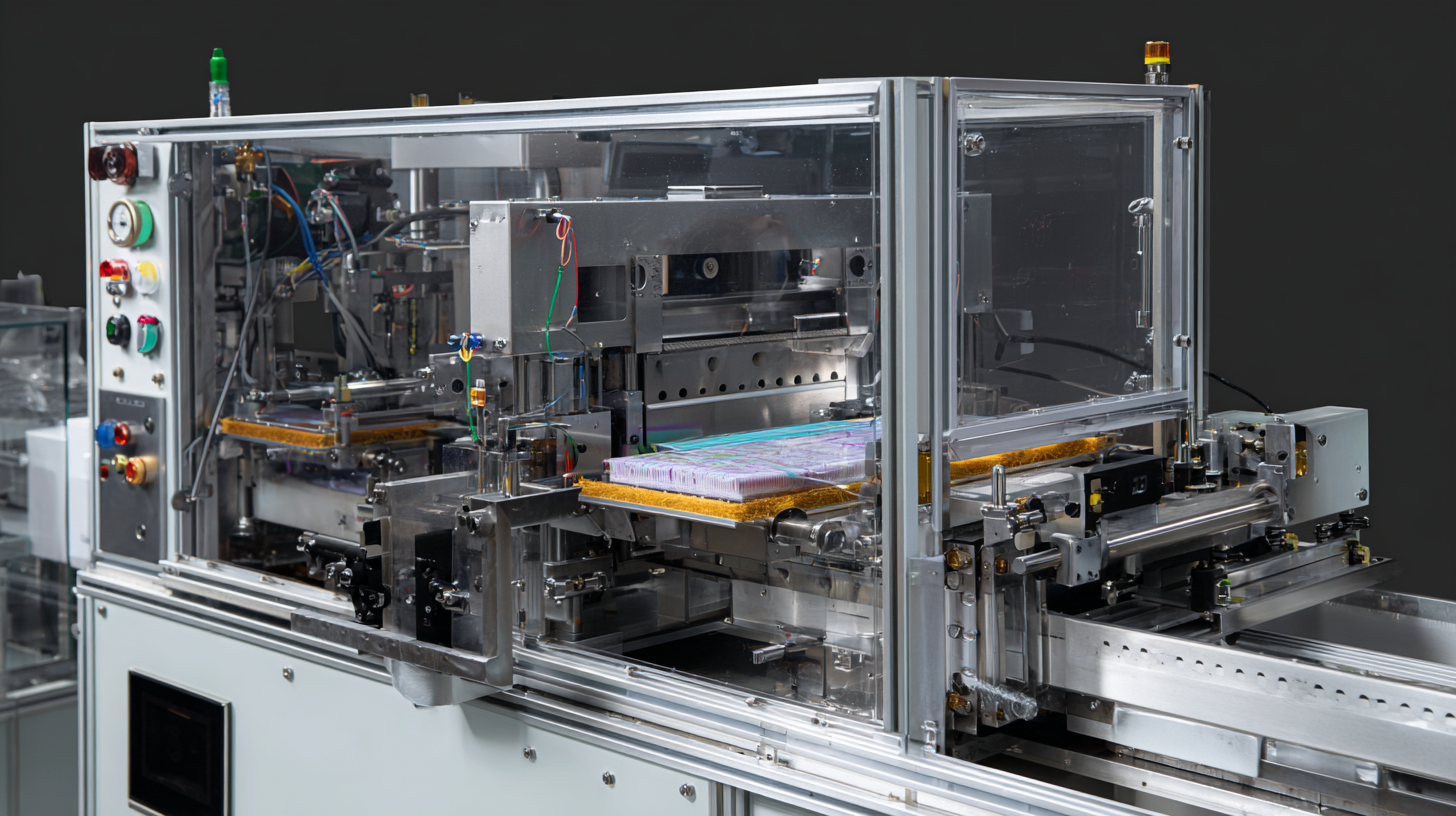

As the packaging industry moves towards 2025, automation stands out as a critical driver for enhancing the efficiency of tray sealing processes. The incorporation of advanced robotics and smart technologies into sealing machines not only streamlines operations but significantly reduces human error. Automated systems can handle a higher volume of trays in less time, allowing food manufacturers to keep pace with growing market demands while maintaining high-quality standards. This shift towards automation means faster production cycles, reduced labor costs, and increased consistency in sealing, which ultimately leads to longer shelf lives for packaged products.

As the packaging industry moves towards 2025, automation stands out as a critical driver for enhancing the efficiency of tray sealing processes. The incorporation of advanced robotics and smart technologies into sealing machines not only streamlines operations but significantly reduces human error. Automated systems can handle a higher volume of trays in less time, allowing food manufacturers to keep pace with growing market demands while maintaining high-quality standards. This shift towards automation means faster production cycles, reduced labor costs, and increased consistency in sealing, which ultimately leads to longer shelf lives for packaged products.

Moreover, sophisticated software integration plays a pivotal role in the future of tray sealing. With real-time data analytics, manufacturers can monitor production lines efficiently, predicting maintenance needs before they become costly breakdowns. Machine learning algorithms can also optimize sealing parameters based on various factors such as product type and environmental conditions, ensuring that each seal is airtight and secure. This level of precision enables businesses to enhance food safety and reduce waste—key concerns in today’s eco-conscious market. As these innovations unfold, the role of automation will undoubtedly continue to transform the landscape of tray sealing processes, making it an exciting time for industry stakeholders.

Sustainability Trends: Eco-Friendly Materials in Tray Sealing Solutions

As we approach 2025, sustainability is taking center stage in the realm of tray sealing solutions. Food and beverage manufacturers are increasingly recognizing the urgent need to adopt eco-friendly materials in their packaging practices, driven by both consumer demand and regulatory pressures. Innovations in this space are not just limited to reducing plastic usage; they also encompass the development of renewable and recycled materials that can maintain product integrity while minimizing environmental impact.

One prominent trend is the integration of fiber-based materials that offer a sustainable alternative to traditional plastics. These advancements in packaging design are crucial, as they allow for convenience without compromising on ecological responsibility. Additionally, the focus on modified atmosphere packaging is leading to extended shelf life for products, reducing food waste while enhancing customer satisfaction.

Tip: When exploring packaging options, consider materials that are certified compostable or recyclable to further enhance your sustainability efforts.

Tip: Stay informed about industry events and innovations, as many forward-thinking companies are showcasing their latest sustainable packaging solutions, paving the way for best practices in the industry.

Embracing these sustainability trends in tray sealing machines will not only align manufacturers with consumer preferences but also contribute to a healthier planet.

Smart Packaging: Integrating IoT into Tray Sealing Machines

The landscape of tray sealing machines is on the brink of a transformative overhaul, with the integration of Internet of Things (IoT) technology at the forefront. As the market for smart packaging is expected to grow at a CAGR of 7.5% between 2023 and 2028, industries are eagerly embracing innovations that enhance efficiency and reliability. IoT-enabled tray sealing machines provide real-time data analytics and remote monitoring, allowing manufacturers to optimize production processes and reduce waste. According to a recent report by MarketsandMarkets, the smart packaging market is projected to reach USD 56.4 billion by 2025, underscoring the significant role that technology will play in the future of food packaging.

Incorporating IoT into tray sealing processes not only improves operational efficiency but also enhances product traceability, a priority for many consumers today. The ability to track packages throughout the supply chain ensures transparency and aligns with the increasing demand for sustainable practices. Additionally, smart packaging solutions can help in predicting maintenance needs, significantly decreasing downtime and operational costs.

Tips: When considering an upgrade to IoT-enabled tray sealing machines, assess your current production workflows to identify key areas for improvement. Investing in training for your staff is also crucial, as they will need to adapt to new technologies and processes. Lastly, ensure that your equipment is compatible with existing systems to maximize the benefits of smart packaging solutions.

Consumer Preferences Shaping Innovations in the Tray Sealing Industry

Consumer preferences are playing a pivotal role in driving innovations within the tray sealing industry. As customers become more environmentally conscious, manufacturers are compelled to adopt sustainable materials and processes. Biodegradable films and recyclable trays are gaining traction, addressing the growing demand for eco-friendly packaging solutions. Additionally, convenience has taken center stage, with consumers seeking easy-to-open designs and portion-controlled packaging that fits their busy lifestyles. As a result, companies are investing in advanced sealing technologies that cater to these changing needs while ensuring product freshness and safety.

Moreover, the shift towards transparency and product information is influencing design and functionality trends in tray sealing machines. Consumers are increasingly interested in knowing the origins of their food and the integrity of the sealing process. This has led to innovations such as tamper-evident seals and smart packaging that provides real-time product information. Manufacturers that align their innovations with these consumer-driven trends are likely to succeed in an increasingly competitive market. Emphasizing the importance of consumer feedback in the development process, companies can create tailored solutions that resonate with their target audience, ultimately shaping the future of the industry.

Future Innovations in Best Tray Sealing Machines Shaping 2025 Industry Trends

| Innovation Focus | Key Features | Consumer Preference Driver | Projected Impact (2025) |

|---|---|---|---|

| Automation Integration | Increased speed and efficiency in sealing processes | Demand for faster production times | High due to reduced labor costs |

| Sustainability Initiatives | Use of eco-friendly materials and processes | Rising consumer awareness of environmental issues | Significant as consumers choose sustainable options |

| Smart Technology | IoT connectivity for real-time monitoring | Preference for enhanced user control and customization | Moderate to high based on tech adoption rates |

| Enhanced Safety Features | Automated safety checks and alerts | Growing concern for worker safety | High as prioritization of safety increases |

| Customizable Solutions | Machines tailored for specific packaging needs | Desire for brands to differentiate their products | High as competition drives innovation |